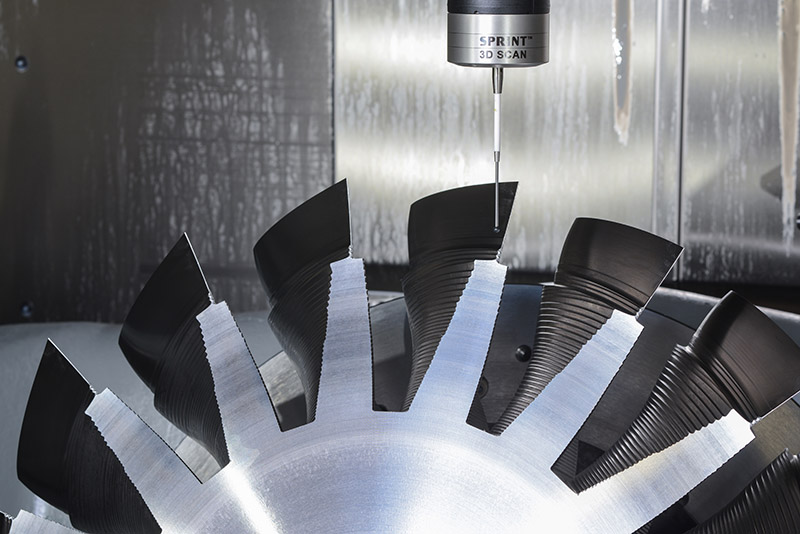

Manufacturing of Ni-or Ti-Blisks with (semi-) finishing strategies

Which semi finishing strategy (milling) is best suited regarding roughing and finishing?

Challenge and Motivation

- Selection of an economical semi-finishing strategy is highly influenced by the blade geometry of the blisk, the number of blocks as well as the the finishing and semi-finishing offset.

- Due to high cutting force (Ni-based) and low Young's modulus (Ti-based), distortion of workpiece occurs.

Objective

- Economical and technological evaluation of different semi finishing strategies with focus on

- tool concepts (barrel tool vs. ball end mill) and

- process design (off-set and depth of cut)

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing