ICTM Conference 2017: "Turbomachinery manufacture profits from digitalization and networking"

Over 250 experts from 19 countries attended the fourth International Conference for Turbomachinery Manufacture, the ICTM Conference 2017, held 15 – 16 February in Aachen. There were 20 presentations given by speakers from the companies acknowledged as market leaders in the sector, reporting on the latest developments and emerging technologies for both manufacturing and using turbomachinery and its components in the aviation and power generation industries.

"The turbomachinery manufacturing sector will profit from the trend towards digitalized, networked production" – was one of the principal conclusions of the ICTM Conference this year. Increased efficiency and reduced CO2-emissions are high on the list of development targets on the agendas of turbomachinery manufacturers; this applies both in the aviation and in the power generation sectors. It is first and foremost the production of particularly light-weight, heat resistant and complex components in ever shorter innovation cycles which presents technological challenges. It is anticipated that these will be overcome via increasing digitalization of production. The speakers and visitors to the conference agreed unanimously that entirely new concepts and processes are needed in the areas of production and repair.

The list of speakers and visitors to the ICTM conference in Aachen reads like a Who´s Who of turbomachinery manufacturing – and Industry 4.0 was a hot topic

Experts from the central turbomachinery manufacturing companies such as Siemens AG, Rolls-Royce Deutschland Ltd. & Co. KG, MTU Aero Engines AG, MAN Diesel & Turbo SE or Pratt & Whitney, as well as some from the IT and data processing sectors represented by SAP AG and PTC Inc. among others, elucidated sector-specific aspects of Industry 4.0, additive manufacturing and a range of advanced manufacturing processes, each from their own perspective. In fact, the interaction among these three technology trends and their interfaces is the area which must be managed successfully in order to bring reliable, innovative products to market within the shortest period of time.

Machine manufacturers and technology providers reported on the importance in the current manufacturing environment, of implementing "Smart Manufacturing" approaches to dealing with heavy-duty materials, which are difficult to machine, in order ultimately to ensure zero-defect-production of the costly components. Process digitalization strategies, process control based on the digital twin embodying the complete manufacturing history and approaches to networking machines and systems with big data algorithms in cloud-based company networks also dominated the subsequent discussions.

"Better gas turbines are crucial in the fight to reduce CO2-emissions in commercial aviation"

The two-day event which attracted one of the highest attendances in its history, provided clear evidence and reliable statistics in the closing presentation by Dr. Alan Epstein from Pratt & Whitney to show that as far as the development and deployment of gas turbines in aviation and power generation are concerned, there is a long future ahead: advances in turbomachinery manufacturing are fully expected to continue to make the most significant contribution to the reduction of net CO2-emissions in commercial aviation.

Promoting dialogue and implementing innovations

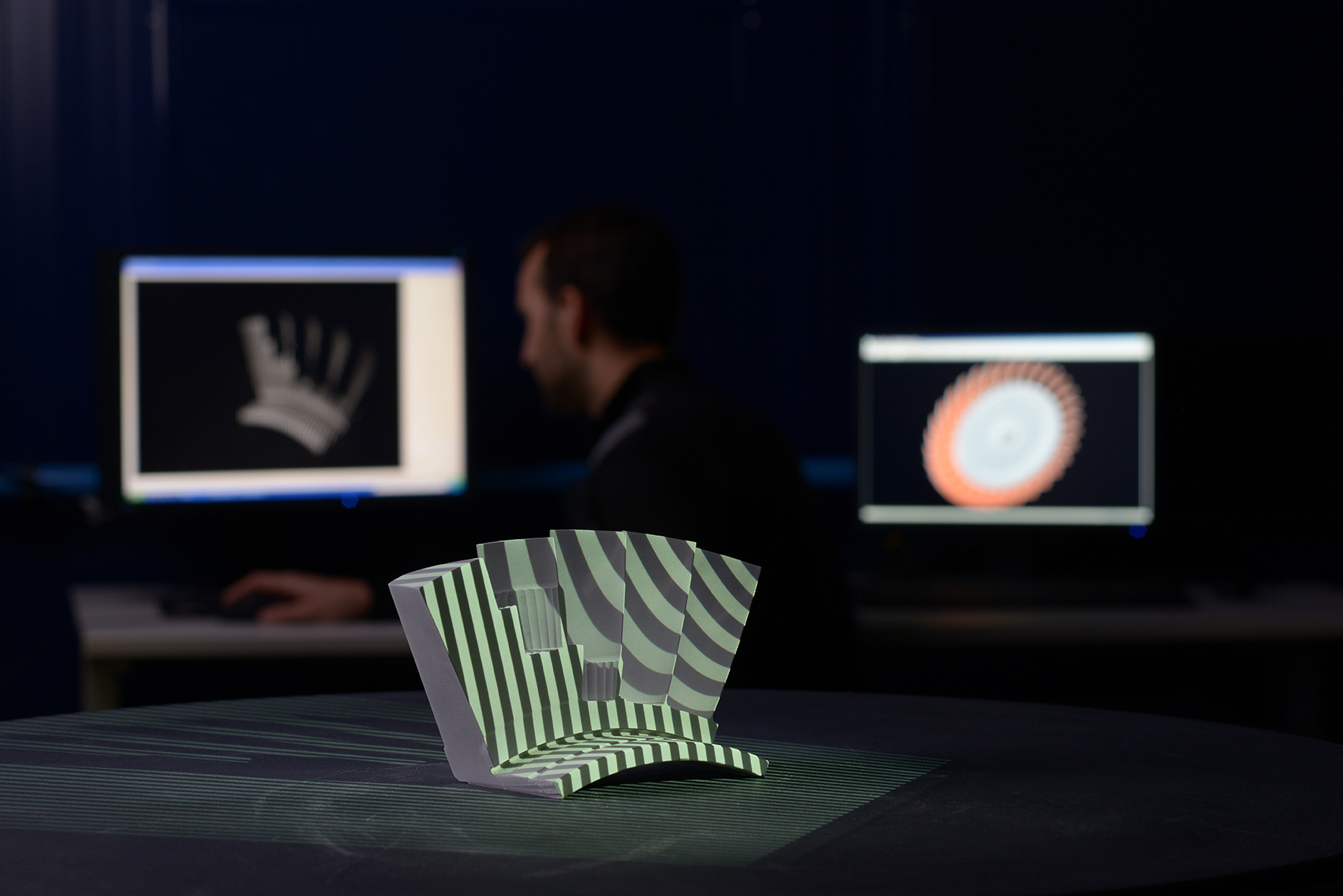

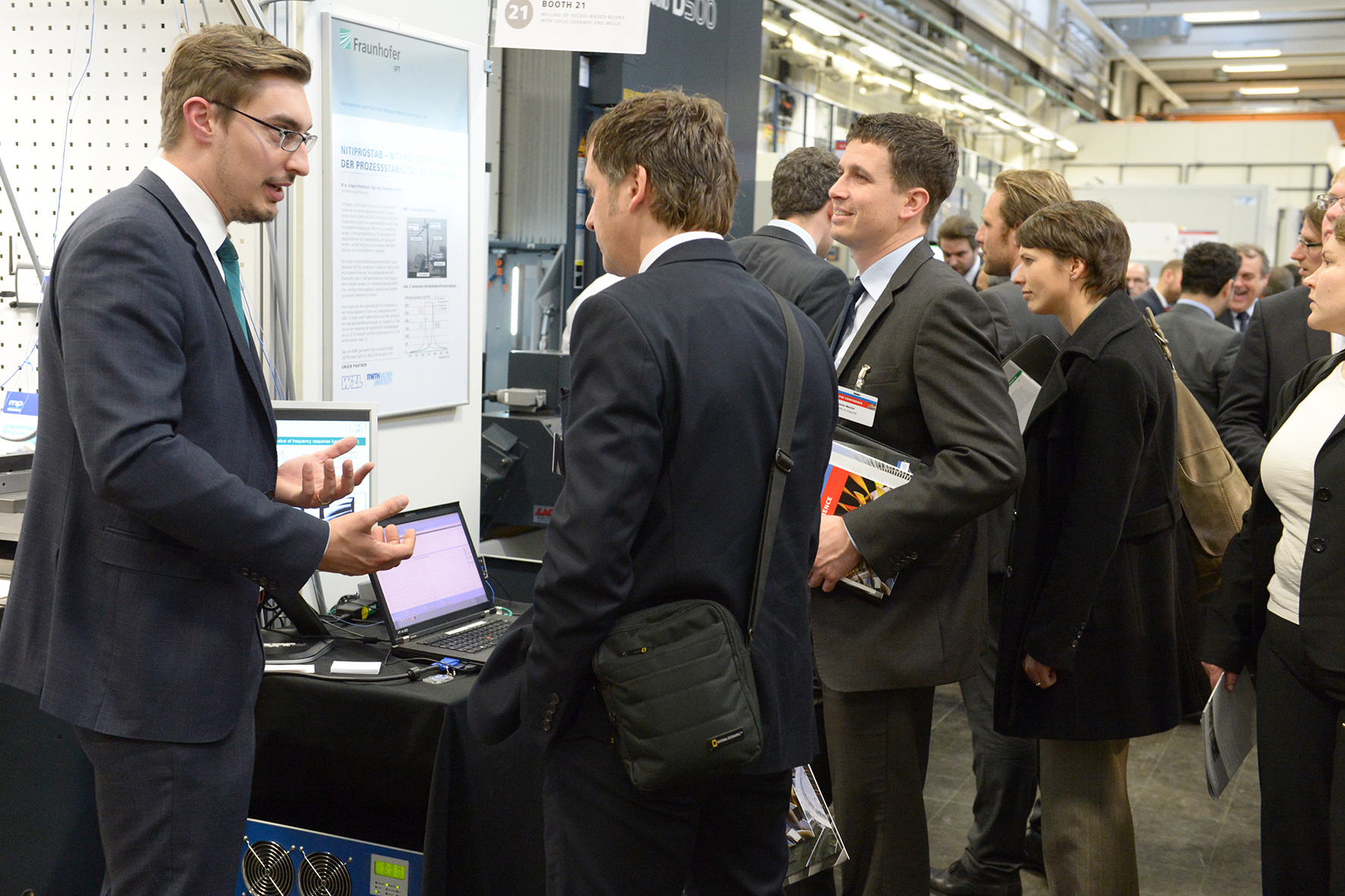

In addition to organizing the program of lectures held at the Eurogress in Aachen, the conference hosts, the Fraunhofer Institute for Laser Technology ILT and the Fraunhofer Institute for Production Technology IPT also opened their machine shops and laboratories to the conference visitors at the end of the first day of the conference: all those who attended the conference had the opportunity to see at first hand live demonstrations and individual presentations of current trends in technology at a total of 44 stations at the host institutes as well as at the neighboring Laboratory for Machine Tools and Production Engineering WZL at the RWTH Aachen University and to explore the marginal areas of production research in the field of turbomachinery manufacturing.

According to the organizers, the Aachen Conference, which is closely associated the specialist areas of research and development pursued by its namesake, the "International Center for Turbomachinery Manufacturing", plans to stimulate dialogue in the turbomachinery sector again in two years´ time. "We are delighted to hear that our efforts to inject fresh momentum into the dialogue among manufacturers, suppliers and research facilities has been successful", Dr. Thomas Bergs, Managing Director of the Fraunhofer IPT sums up the two-day conference as follows,"The lively exchange of ideas during the conference and with our partners from the ICTM Center will help both parties to drive progress in developing innovations more swiftly and to implement them in industrial practice." The dates of the next ICTM Conference have already been set provisionally for 6 and 7 February 2019.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing