Benchmarking of automatic non-contact measurement techniques

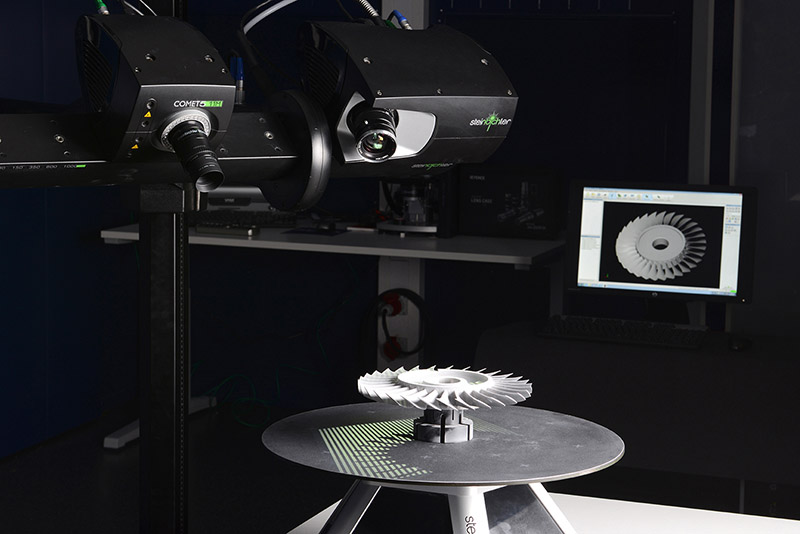

Which non-contact metrology solutions can be used for fast and automatic quality inspection?

Challenge and Motivation

- Turbomachinery components require precise surface quality for optimal performance and longevity.

- Defects or roughness directly affect the quality.

- Current inspection methods are time-consuming and often rely on manual or contact techniques.

Objective

- Benchmarking of different non-contact metrology technologies for maturity assessment, automation possibilities, cost and accuracy criteria.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing