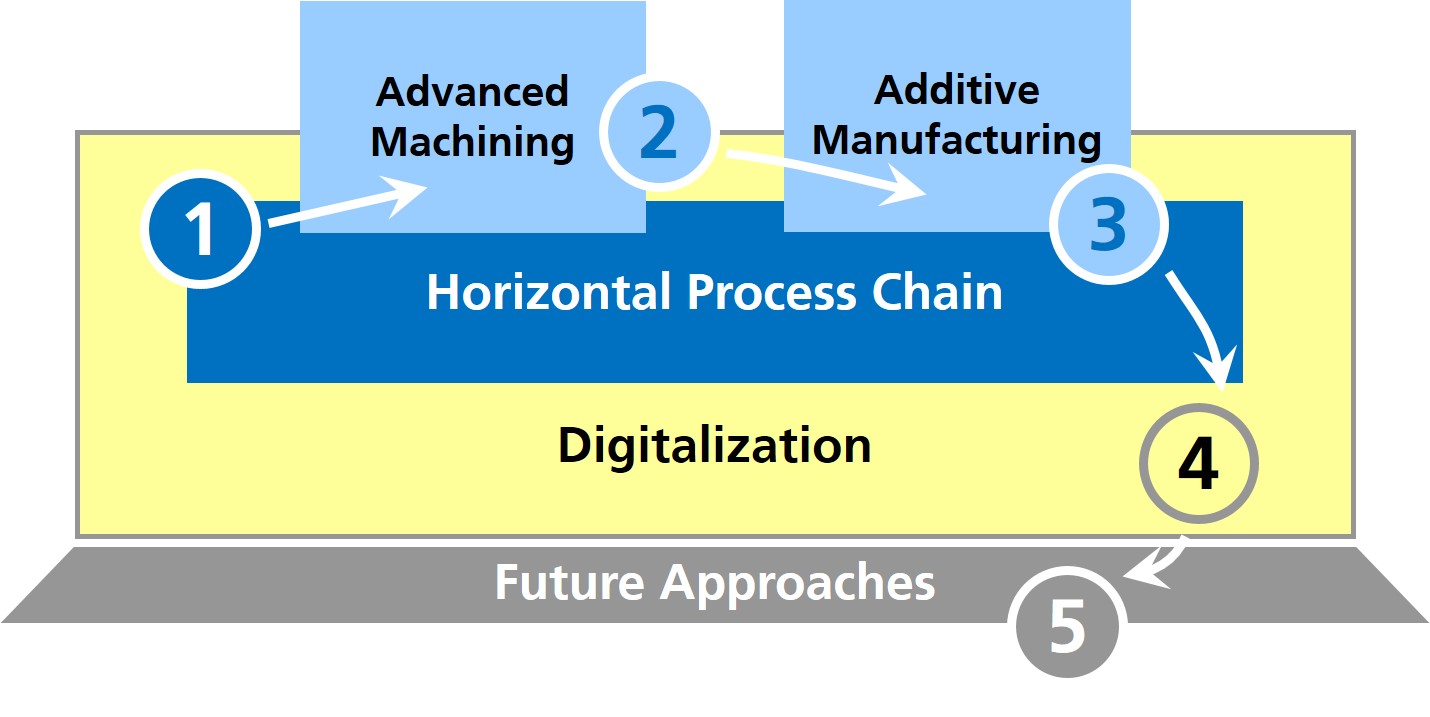

Based on the fixed annual contributions of each of the ICTM Industry Partners a set of Collaborative R&D Projects is conducted. These projects allow high synergies and significant benefits of cooperation in particular for pre-competitive issues. All of the Collaborative R&D Projects are defined and conducted on an annual base integrating all partners to input their particular demands and participate in the results. Within the projects specific technology improvement for individual manufacturing processes as well as comprehensive improvement of the entire manufacturing chain also with regard to Digitalization is addressed. The Collaborative R&D Projects are selected by the ICTM Partner Community on the Annual R&D Meeting based on the developed ICTM Roadmap for collaborative R&D.

This roadmap covers a mid-term range and will be extended continuously to derive an annual set of collaborative R&D projects each year. As it is proprietary information to the ICTM, it cannot be disclosed to public in detail.

To complement the annual selection of collaborative R&D projects according to its roadmap the ICTM continuously screens funding opportunities that allow to address strategic topics, which could not be included because of limited collaborative annual budget. To stay independent and without constraints result of the internationality of the Partner Community, the ICTM is able to set-up sub-consortia in addition to the Partner Community with regards to particular funding projects.

Based on the ICTM Roadmap the following projects will be conducted in 2026:

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing