Manufacturing of Ni- and/or Ti-Blisks – First steps towards autonomous and self-optimized CAM planning

Which optimization algorithms are suitable for optimizing NC programs for blisk finish machining?

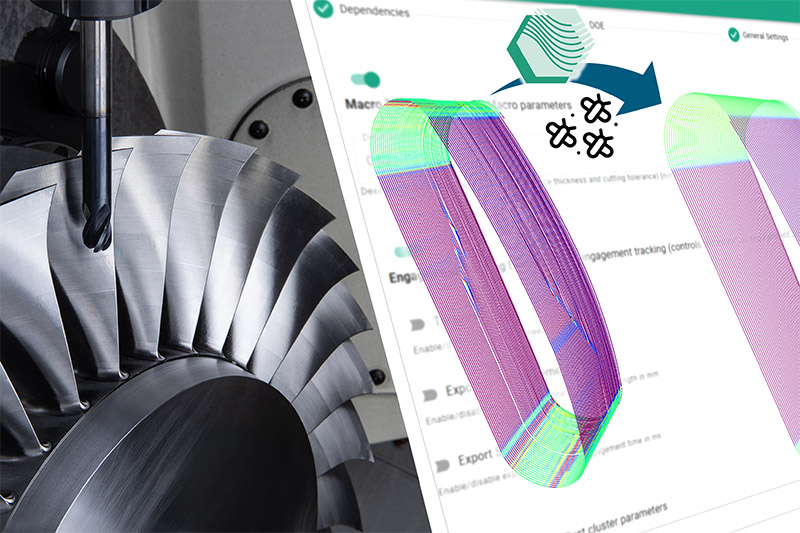

Challenge and Motivation

- Given a target geometry and a machine, the goal is to design the best possible process.

- CAM parameters influence part quality non-trivially.

- Global/local process optima are often unknown.

Objective

- Automatic CAM optimization of KPIs, i.e. cycle time, part quality, force limits, etc.

- Investigate different optimization algorithms for blisk machining during process planning.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing