Active Vibration Reduction

What is the potential of active vibration reduction systems?

Challenge and Motivation

- Vibrations in milling lead to higher surface damages, higher tool wear and higher sound emissions.

- The reduction of vibrations and the avoidance of instabilities will raise the milling efficiency significantly.

Objective

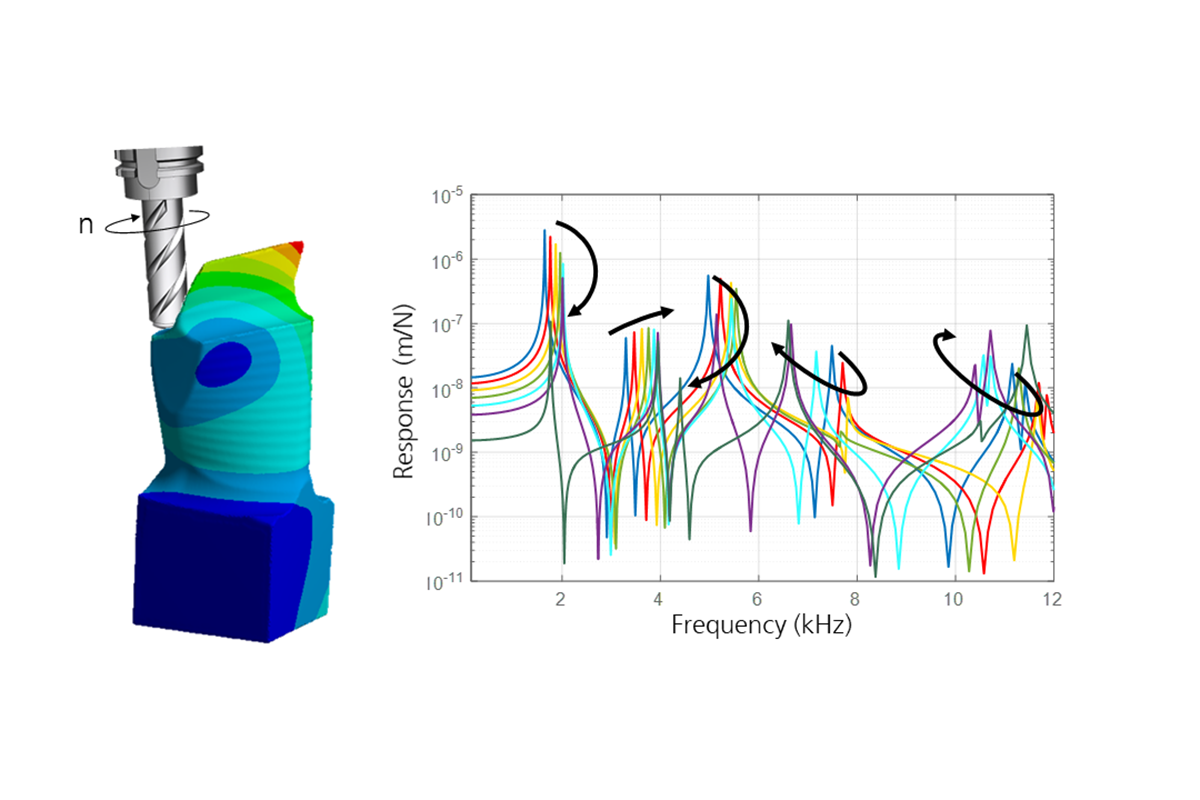

- Analysis of the varying demonstrator dynamics for a curved geometry.

- Vibrations reduction due to advantageous spindle speeds.

- Active vibrations damping by using of piezo actuators during the milling process.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing