ICTM Collaborative R&D 2019

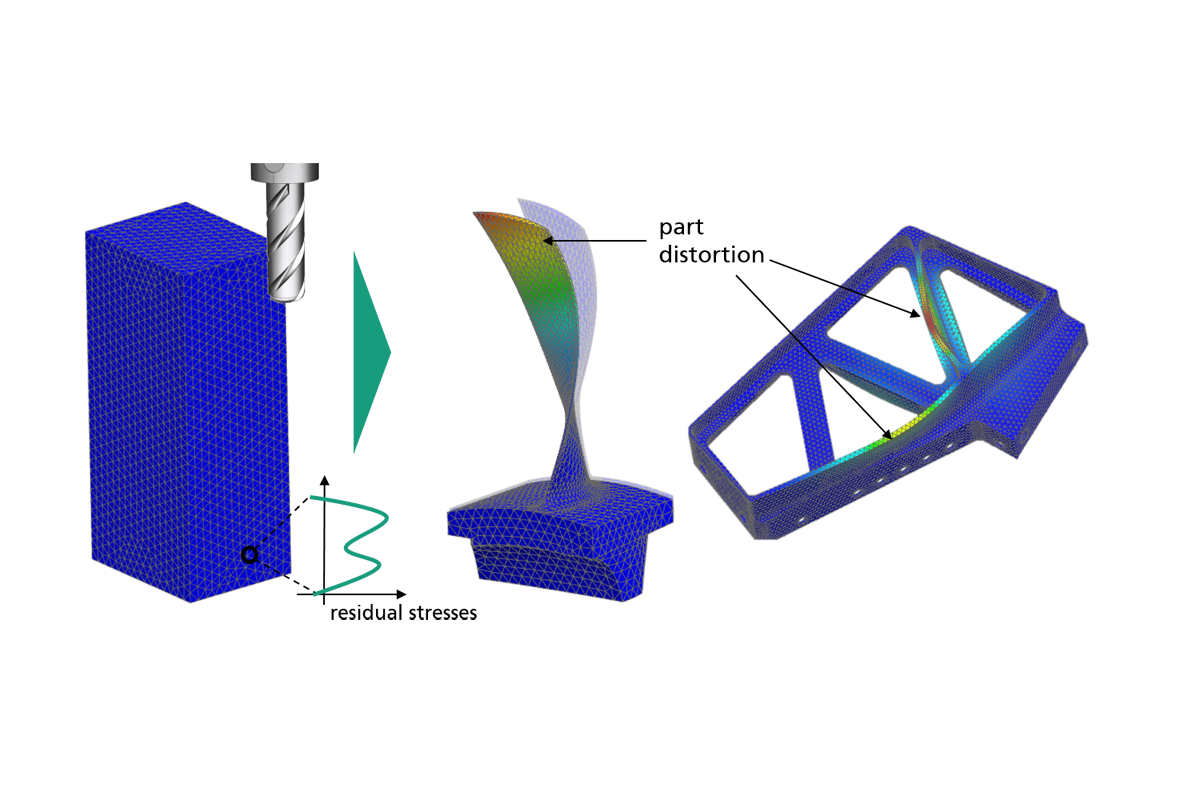

Analysis of Part Distortion due to Residual Stress in Milling (study)

How can part distortion of a thin-walled component be analyzed during milling?

Challenge and Motivation

- Residual stresses can lead to significant dimensional errors through part distortion.

- A study by Boeing, based on four aircraft programs, estimated the rework and scrap costs related to parts distortion comes to in excess of 290 million dollars.

Objective

- Identification of common methods to analyze part distortion due to residual stress in milling.

- Experimental demonstration of part distortion during milling.

- Modelling and simulation of part distortion in milling.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing