ICTM Collaborative R&D 2020

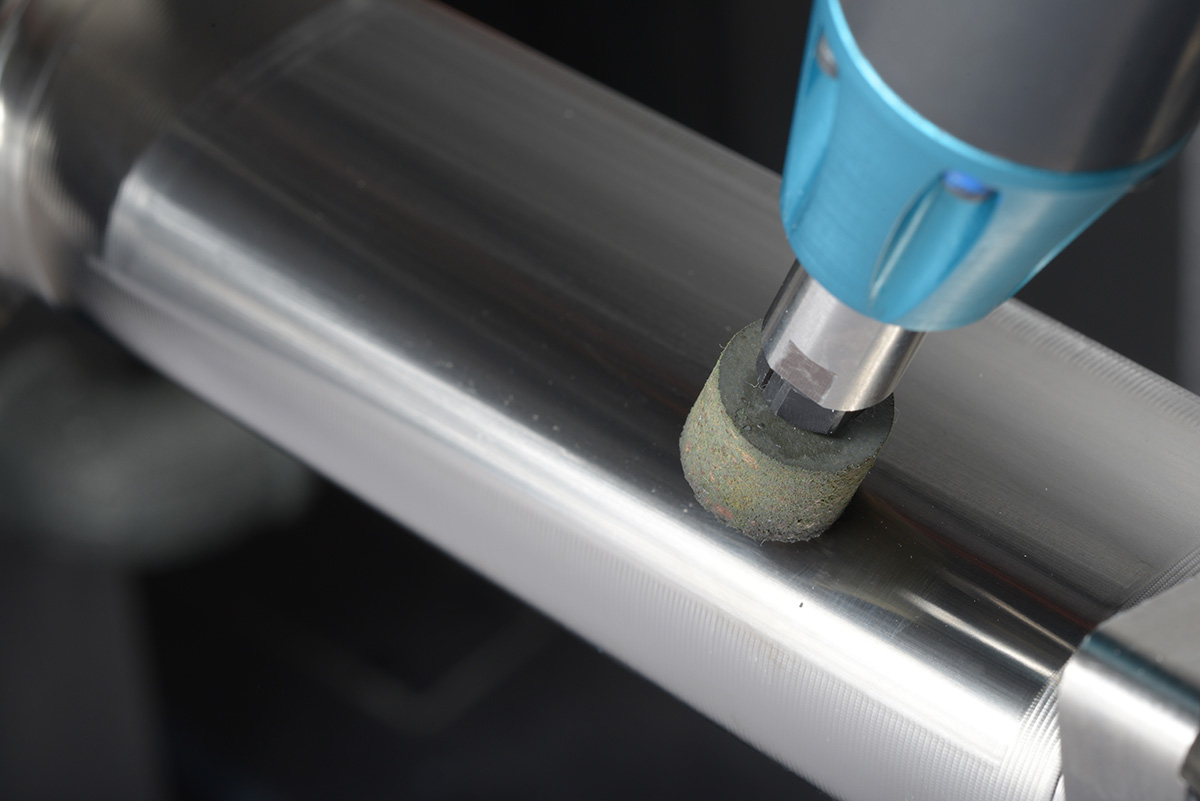

Benchmark of Grinding/Polishing Technologies to Finish Blades

Which technical and econimical potentials offer the addressed grinding/polishing processes?

Challenge and Motivation

- Blades and Blisks demand high quality standards in shape accuracy and surface quality. The complex geometries demand a high effort milling process.

- Finishing of Blades and Blisks is done today with e.g. PECM, vibratory grinding or manual processes.

- Robot-based and CNC-machine integrated finishing technologies could decrease the manufacturing time by keeping the same quality standards.

Objective

- Evaluation of technical and evonomical performance of the grinding/polishing technologies for single Blades (incl. potential/issues regarding Blisk finishing).

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing