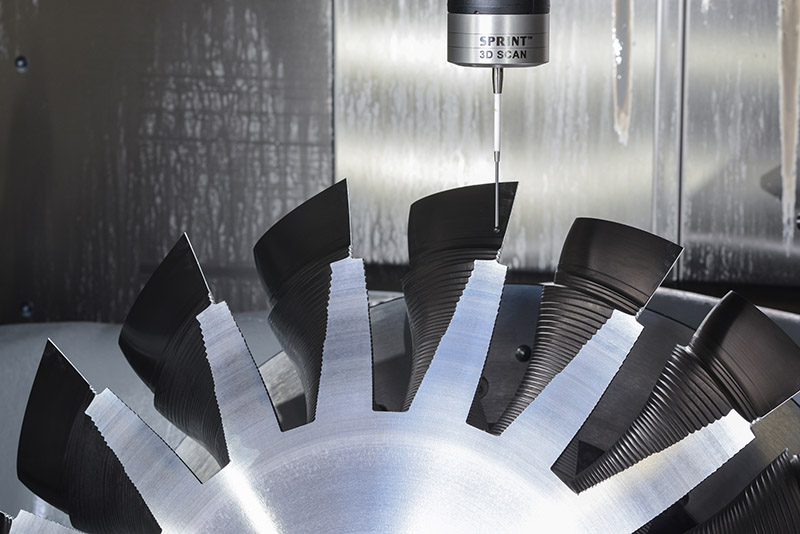

Manufacturing of Ni- or Ti-Blisks with advanced roughing strategies

Which roughing strategy in milling is best suited with regard to different blisk designs?

Challenge and Motivation

- The selection of an economical roughing strategy is highly influenced by the blade geometry of the blisk.

- Lack of process knowledge makes the selection of a suitable roughing strategy difficult.

Objective

- Economical, technological and ecological evaluation of different roughing strategies (e.g. conventional, high-feed milling, side milling, trochoidal milling, plunge milling).

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing