ICTM Collaborative R&D 2020

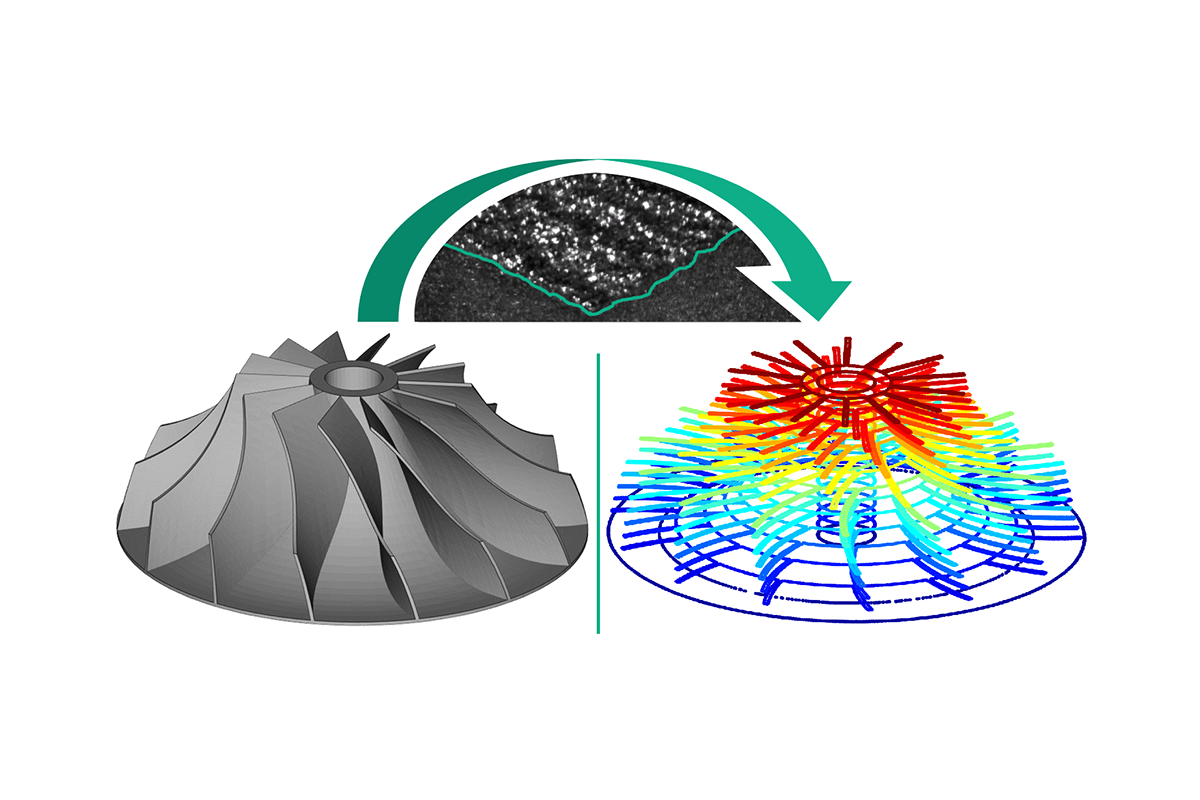

In-situ Monitoring in LPBF for a Digital Representation of Part Geometry

Can the actual geometry be detected during the LPBF process using a high-precision optical system?

Challenge and Motivation

- Properties of LPBF-manufactured parts are a black box during production.

- Geometry of specimens can only be determined outside the machine after manufacturing.

Objective

- Implement a high-resolution optical monitoring system to record the powder bed after each layer.

- Determine the layer-wise contours from the images.

- Aggregate to a digital model of the part during production.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing