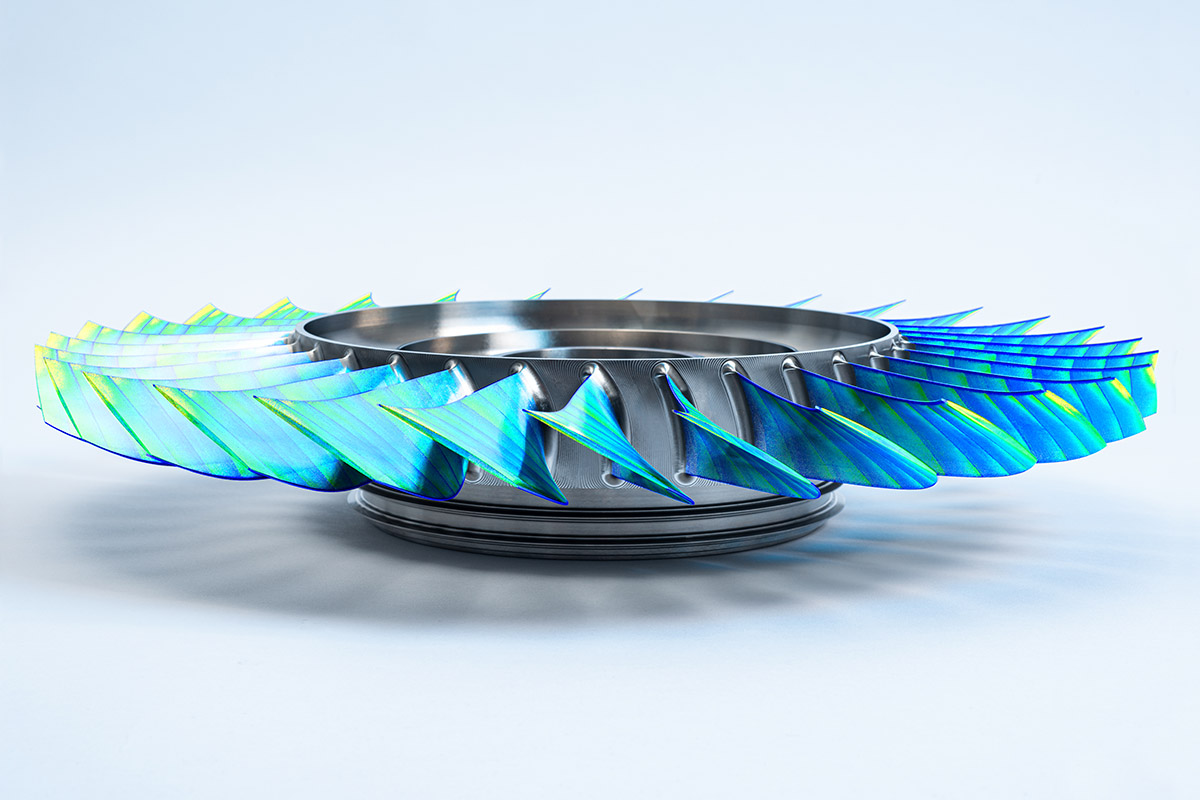

Optimized Blisk Series Production by Use of Tool Path Compensation Methods

Do tool path compensation methods improve product quality and process stability in Blisk production?

Challenge and Motivation

- Many different influences such as wear, tool and workpiece deflection cause geometric form errors during milling.

- These geometrical errors reduce the process capability and lead to tolerance violations.

Objective

- Application of cutting simulation to compensate geometrical deviations in the process planning.

- Evaluation of the method in the use case of 5-axis milling of downscaled Blisk’s.

ICTM Aachen – International Center for Turbomachinery Manufacturing

ICTM Aachen – International Center for Turbomachinery Manufacturing